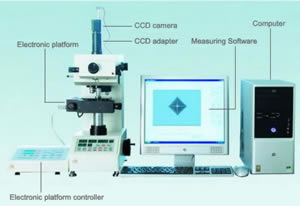

Hardness Tester

Hardness refers to a property of a solid material that resists permanent deformation and form due to a force. In industry, especially in the manufacture and testing of many materials, as well as in welding, knowing the hardness is of great importance. Is . Hardness can be expressed in terms of different units defined for different materials. For example, the hardness of minerals or minerals is in Mohs scale, which is compared between 1 and 10, based on the scratch of one material by another, and the highest number, 10, is for diamonds. Other scales are used in the industry such as Rockwell, Vickers and Brinell. These methods, known as indentation hardness methods, are commonly defined for a variety of metals and are measured by comparing the intensity and depth of a standard-shaped projectile on a test piece due to a fall, based on tables that can be They become each other. In addition to the cases mentioned, different units of salinity (shore) such as salinity A and D (shore A, D) are also considered for hardness testing of rubber and polymeric materials, which is measured with a rubber hardness tester (Durometer).

Hardness refers to a property of a solid material that resists permanent deformation and form due to a force. In industry, especially in the manufacture and testing of many materials, as well as in welding, knowing the hardness is of great importance. Is . Hardness can be expressed in terms of different units defined for different materials. For example, the hardness of minerals or minerals is in Mohs scale, which is compared between 1 and 10, based on the scratch of one material by another, and the highest number, 10, is for diamonds. Other scales are used in the industry such as Rockwell, Vickers and Brinell. These methods, known as indentation hardness methods, are commonly defined for a variety of metals and are measured by comparing the intensity and depth of a standard-shaped projectile on a test piece due to a fall, based on tables that can be They become each other. In addition to the cases mentioned, different units of salinity (shore) such as salinity A and D (shore A, D) are also considered for hardness testing of rubber and polymeric materials, which is measured with a rubber hardness tester (Durometer).

In mechanical and metallurgical sciences, its hardness parameter and gauge play an important role, especially after furnace operations and hardening. Depending on the type of material, different standards, units, and methods for measuring hardness have been developed. The most common methods are the Rockwell, Vickers, and Brinell methods. The discussion of these standards will be discussed in detail elsewhere. کرد.

This device, which is portable and portable, works in such a way that the projectile, which is conical in shape and has a special ball with a high degree of hardness installed on it, is thrown towards the metal surface by a cylindrical device with a spring. And by measuring its return speed, its hardness can be measured.

The basis of most other devices is to create a point of effect on the metal surface, and by measuring the depth of this point, they measure the effect and the diameters of the role created on the metal surface, and then by matching those dimensions with a pre-prepared table. This is a well-known Leeb rebound test measurement technique.

- Popular products

German laser thermometer with external thermocouple K tool 1725

Level controller / roller blade switch for solids and powders, model 1872

Industrial Laser Thermometer Instrument 1727

12-channel temperature recorder thermocouple tool 1189